Have you set the right KPIs for effective CPI? Are you optimizing your operations for a synergistic effect?

It can be difficult to navigate a landscape of latest buzzwords, trending terms, and a jungle of jargon. How do you find practical and meaningful actions that can be readily implemented to provide significant benefits? Pulse is here to help on your journey to procure improvement.

Continuous process improvement (CPI) is frequently associated with cutting costs and increasing efficiency. But CPI, at its most elemental, can be distilled into two steps: examine and act. Whether it’s a specific procurement project, your standard procurement process, managing customer and client relationships, or maintaining a budget, the first step is to review all available information within your area of focus. Then, step two, it is time to formulate and implement a plan of action.

3 Approaches to Start Improving Your Procurement Processes

#1: Start Strategic Sourcing

Strategic sourcing aligns procurement practices with broader objectives to create and maintain long-term value. Put the information collected by eProcurement systems to good use with data-driven strategic sourcing. Consider consolidating purchases across agencies to get a bulk discount or narrowing the number of suppliers used for target goods and services to gain leverage in pricing.

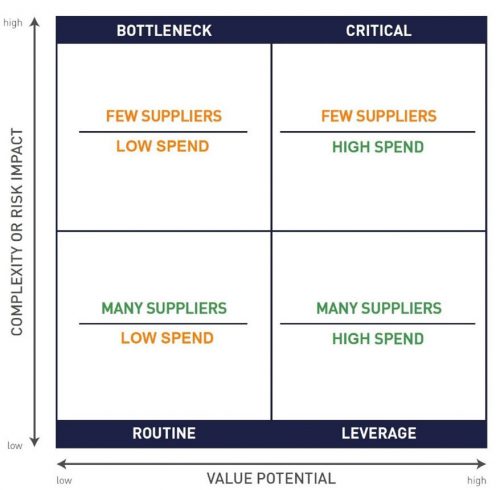

One simple tool that you can use to identify potential areas of value: a quad model, or the Kraljic Matrix.

This model helps you sort contracts into sections determined by purchase volume or contract spend and by the number of suppliers available. Generally, the higher the purchase volume or spend, the greater potential exists to increase value for the state. Procurements with high purchase volume or high spend for goods and services with many qualifying suppliers present the most opportunity. Leverage your spend data to negotiate lower prices, better terms and conditions, or additional services.

This model can also identify risk. High spend contracts for specialized goods and services with few available providers in the marketplace puts greater importance on managing relationships with those suppliers. When there are few suppliers available, potential exists for a bottleneck in your supply chain. And while low-spend contracts with few suppliers may present less fiscal risk, they still present significant risks you should monitor.

For more about strategic sourcing, check out NASPO’s Procurement Toolbox: Strategic Sourcing edition.

#2: Consider Sustainability

Incorporating sustainability is another way to eliminate or reduce waste and add value. Include the total cost of ownership (TCO) into specifications and evaluation criteria to help identify which sourcing options represent the best long-term value. Most environmentally-preferable products present an opportunity to reduce utility costs and lower maintenance and disposal costs, both direct and indirect. Replacing short-use or disposable goods with more durable versions can reduce total purchase volume and spend.

Ecolabels can assist public procurement officials in locating certified commodities and services that have met independent rigid testing requirements, as most maintain a catalog of approved products. Using these lists can save time and resources on specification development. Ecolabel Index offers details on prominent ecolabels across the globe for all manner of goods and services with links to their websites and catalogs.

States that have already incorporated sustainability into their procurement projects and process offer prime examples of the benefits achieved, often by publishing public reports showing the fiscal and environmental impacts. Massachusetts’ EPP Report shows an estimated $3.18m in savings for 2020. The state of Maryland offers a great testimonial to the fiscal benefits of including sustainability in your procurement with their “Saving Money by Buying Green” Fact Sheet.

#3: Adopt Project Management Practices

In Can’t We Just Blame Bureaucracy?, Pulse demonstrates how project management concepts can be applied to the procurement process. These are some of the most readily applicable project management steps for your procurement projects:

- Clearly define scope and expectations

- Assign roles and responsibilities

- Set milestones and due dates

- Debrief and record any lessons learned

Collaboration is key for successful project management and procurement process improvement. Input from end users, customer agencies, legal and tech departments, and SMEs may be vital for your project planning phase. Project team members must maintain frequent and effective communication about any progress made, obstacles encountered, and changes needed. Stakeholders should have input in the planning phase and must be kept up to date through completion. This will lead to better customer service and better contract management as well.

Adopting collaborative management and development strategies from the corporate and tech sectors, such as Agile, Lean, and Kaizen, has become increasingly popular in the public sector in recent years. NASPO recently hosted a webinar discussing the use of the Agile Sprint approach to RFP development.

Procurement U offers a suite of courses to train your staff in project management concepts. Explore them here.

For more NASPO resources on continuous process improvement, check out: